Element Science – Adhesive Testing

Data-driven adhesive selection, precision dispensing, and validation testing for sealed injection-molded device housings.

Adhesive selection under a three-way constraint

I was tasked with selecting an adhesive for sealed injection-molded housings that had to meet tensile strength, IP67 ingress, and reworkability requirements simultaneously.

The existing solution (VHB tape) met strength and sealing needs but created excessive peel strength and cleanup cycle time, blocking efficient component recovery and reuse.

Test & Process Engineer (Mechanical / Controls) — developed the dispensing workflow, executed strength + ingress validation, and made the final adhesive recommendation based on measured performance.

Outcome

The program’s definition of done was a defensible, test-backed recommendation that met the strength + IP67 requirements while reducing rework friction versus VHB.

Objective

Replace VHB tape with a silicone adhesive that maintained sealing and tensile performance while lowering peel strength and cleanup time to enable component harvesting and reuse.

Context

The housings were injection-molded plastic enclosures designed to protect expensive internal components. While the existing VHB approach sealed well and held strong, it created a painful downstream issue: removing residue added significant cycle time and made reuse/recycling workflows inefficient.

Constraints

- • Tensile strength: adhesive joint must withstand ≥ 50 lb pull force

- • Sealing performance: IP67 ingress compliance

- • Reworkability: peel strength low enough to enable fast cleanup and reuse

- • Process feasibility: controlled dispensing and cure behavior suitable for operations

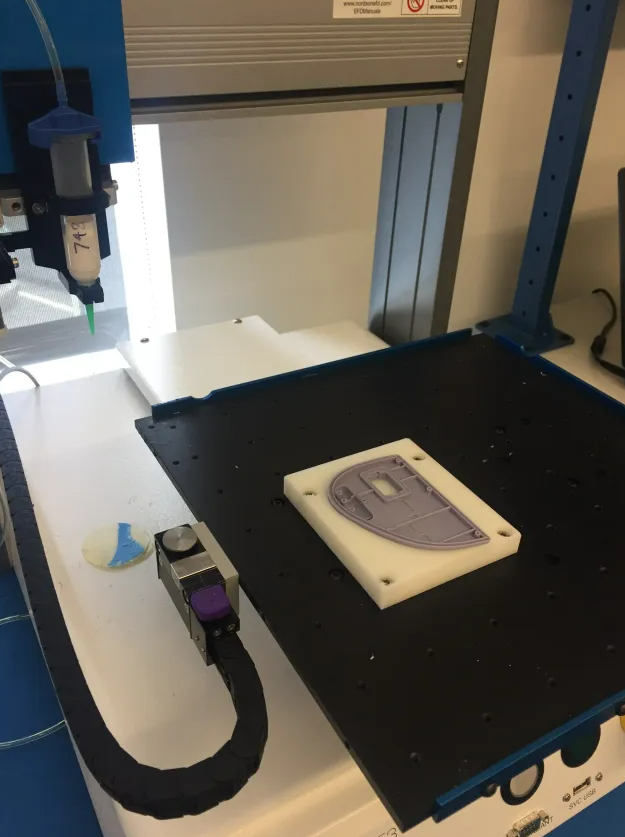

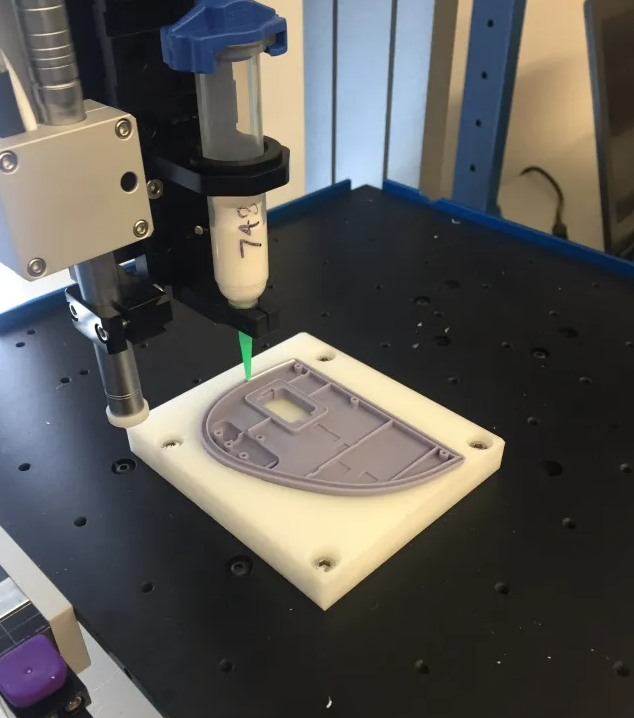

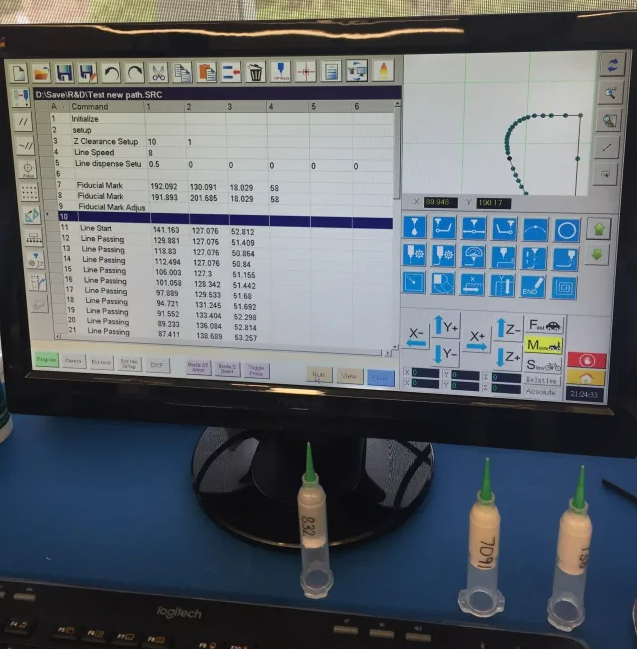

Process development repeatable dispensing

To ensure evaluation reflected adhesive performance (not process variation), I established a stable dispensing workflow and validated consistency through controlled setups and repeatable application geometry.

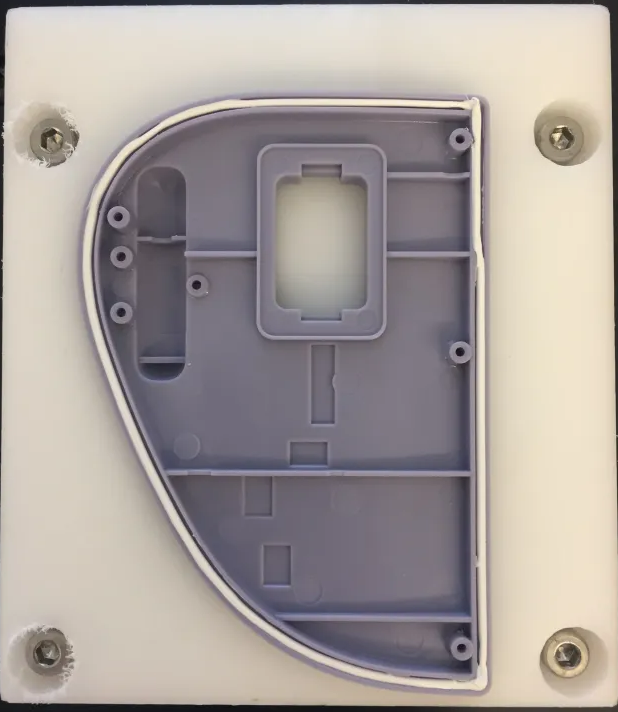

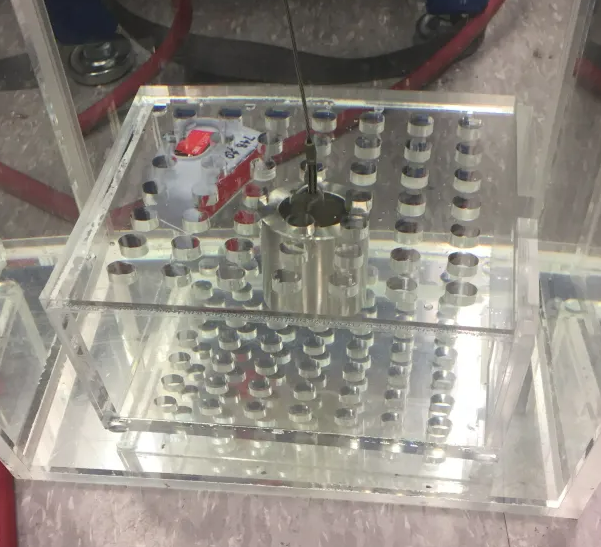

Sealed configuration

Candidate adhesives were evaluated in the same sealed configuration used in production workflows to ensure test results mapped to real operating conditions and rework requirements.

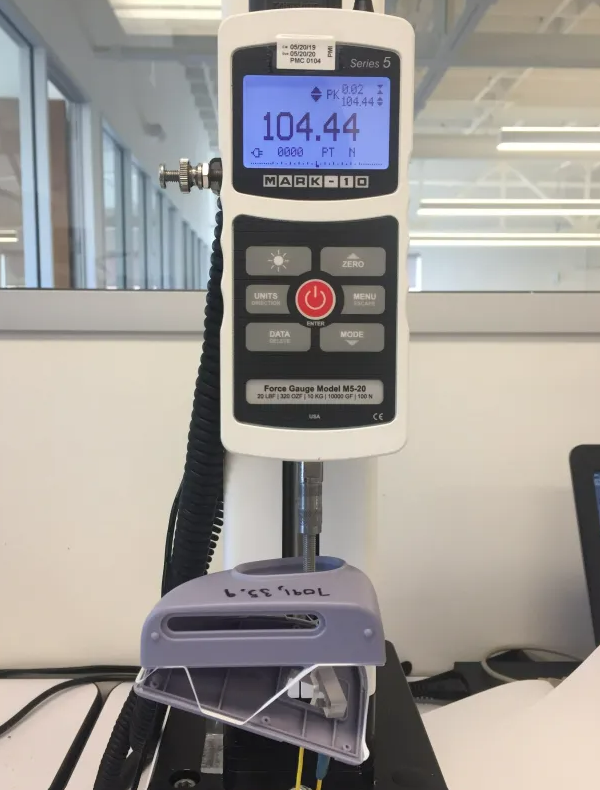

Validation strength + ingress

Adhesives were tested against the full requirement stack. If multiple candidates passed, the final decision was made using the best overall performance across strength, sealing, and practical reworkability.

- • Must pass tensile threshold (≥ 50 lb)

- • Must pass IP67 ingress compliance

- • Among passing candidates, prioritize lower peel strength and faster cleanup for reuse

One-line takeaway

I translate ambiguous material/process constraints into a repeatable test plan, generate clean validation signal, and make an engineering recommendation that balances performance with real operational cost.