Project Hardtail

Product design engineering for a multi-signal scan-and-go shrink-reduction pilot in a live Walmart Neighborhood Market.

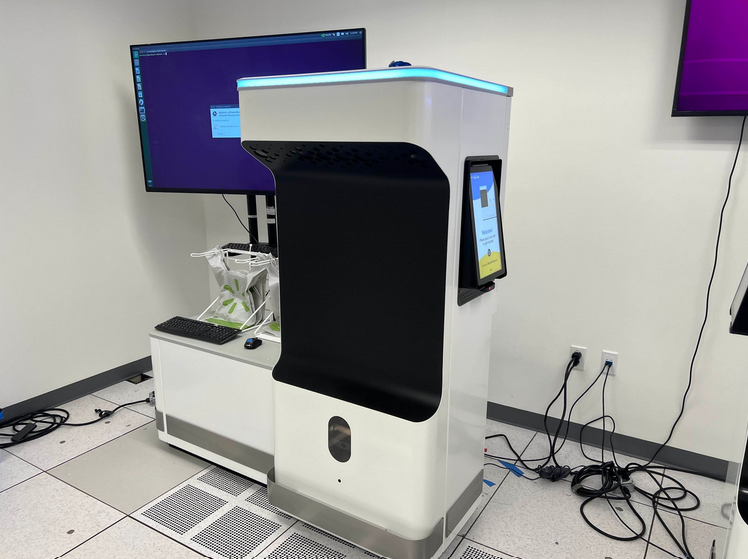

Mechanical-forward case study prototype → field pilot hardware

Hardtail was a pilot unit installed at a Walmart Neighborhood Market in Bentonville, AR to reduce scan-and-go shrink by reducing accidental missed scans.

Product Design Engineer (Mechanical / Systems) — owned the physical architecture and integration of a multi-signal platform (sensing, compute, enclosure, mounting, and serviceability), supporting rapid iteration and in-store pilot operations.

Outcomes

The goal was to deliver a mechanically reliable pilot that could reconcile a customer’s digital basket with the physical cart state and provide clear shrink-reduction signal in real store conditions.

Objective

Build and deploy a store-ready, multi-signal hardware platform that could determine a customer’s basket with high confidence, compare the digital basket to the physical cart state, and define exit criteria to reduce scan-and-go shrink—without adding operational friction.

Context

Scan-and-go improves customer convenience, but it introduces a persistent failure mode: items can be missed during scanning. Hardtail was designed to close that gap by validating whether the cart contents matched what the customer scanned—supporting a smoother customer experience while reducing unintentional shrink.

Multi-signal platform and “brain”

Hardtail used a multi-sensor approach—similar in spirit to Gulfstream, but tuned for scan-and-go validation rather than full checkout—combining identity, perception, and rule enforcement to determine exit criteria.

- • RFID + camera vision for cart-state and item presence

- • Symbology recognition to interpret labels / identifiers

- • Bluetooth handshake between customer phone and Hardtail for session association

- • Basket association (digital cart ↔ physical cart)

- • Exit criteria evaluation using a rules-based + ML decision layer

- • Designed to reduce false positives and avoid customer friction

Constraints

- • Live store environment with continuous public interaction

- • Minimal disruption to store operations and associate workflows

- • Must integrate with existing store layouts and customer scan-and-go behavior

- • High durability, safety, and serviceability expectations

- • Environmental variability impacting perception and RF behavior

Prototype development and integration iteration

Early builds focused on integration feasibility and signal quality—ensuring sensors, compute, and mounting geometry were stable and serviceable enough to survive store operations and produce trustworthy pilot data.

Approach

- • Defined hardware and mechanical requirements from store constraints (footprint, mounting, safety, service access)

- • Integrated sensing + compute into a maintainable architecture

- • Tuned physical geometry to support stable perception and consistent signal quality

Field hardening

Later iterations focused on robustness and maintainability: reducing failure points, improving service access, and making the build more repeatable for sustained in-store operation.

- • More robust interfaces and mounting for repeated public interaction

- • Service access for quick in-store troubleshooting

- • Improved DFM for fabrication and assembly

- • Better alignment between physical geometry and sensing performance

- • Hardened the design based on anticipated pilot wear, failure modes, and servicing needs

- • Insulated wiring with RF resistant lining for decreased signal noise

Key skills demonstrated

Integrated sensing, compute, and enclosure architecture into a store-ready unit, balancing robustness with serviceability.

Designed for durability, safe public interaction, and fast maintenance in a live retail environment.

Supported stable signal quality through physical geometry choices and iteration based on observed failure modes.

Delivered pilot-ready hardware and supported deployment/iteration loops to generate measurable shrink reduction.

I design multi-signal retail hardware that is durable, serviceable, and capable of producing measurable real-world impact.