Project Lightfoot

Mechanical product development of an energy-harvesting system for associate carts—designed, prototyped, iterated, and piloted.

Mechanical product development for an energy-harvesting system

Lightfoot tackled a fundamental systems question: how do you harvest usable energy from associate carts in a way that is mechanically robust, maintainable, and compatible with real retail operations?

Downstream applications (e.g., powering a handheld scanner, charging a device, bridging to a Bluetooth system) and sustainability outcomes were not “side quests”—they were key enablers that justified piloting and created a measurable value narrative.

Product Design Engineer (Mechanical / Systems) — owned mechanical architecture, packaging, prototyping, and iteration from early concepts through pilot hardware; partnered cross-functionally to ensure the physical system reliably generated and delivered usable power.

Outcomes

The primary deliverable was a mechanically validated energy-harvesting platform that could be deployed in real conditions. Secondary outcomes (device enablement + sustainability narrative) provided the “why now” and helped secure pilot traction.

Sustainability outcomes and operational enablement were framed as measurable benefits of solving the core energy harvesting challenge—useful for stakeholder buy-in and scaling decisions.

Objective

Design and build an energy-harvesting system for associate carts that converts real cart usage into reliable, usable electrical power—packaged in a durable, serviceable form factor suitable for retail deployment.

Context

Carts are ubiquitous, high-duty-cycle assets with repeated motion and interactions. The opportunity was to turn that real-world activity into harvested energy while meeting the realities of retail: wear, impact, weathering, maintenance, and deployment constraints.

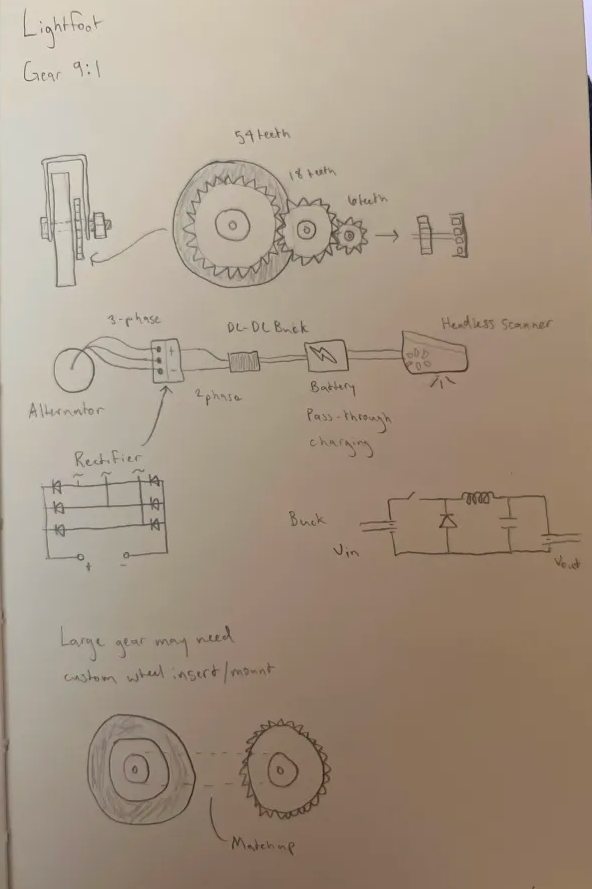

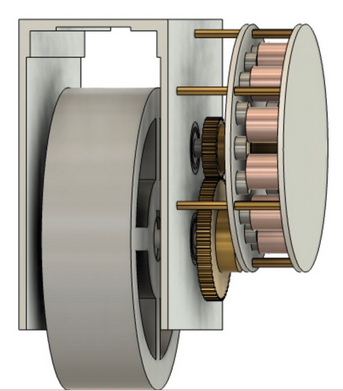

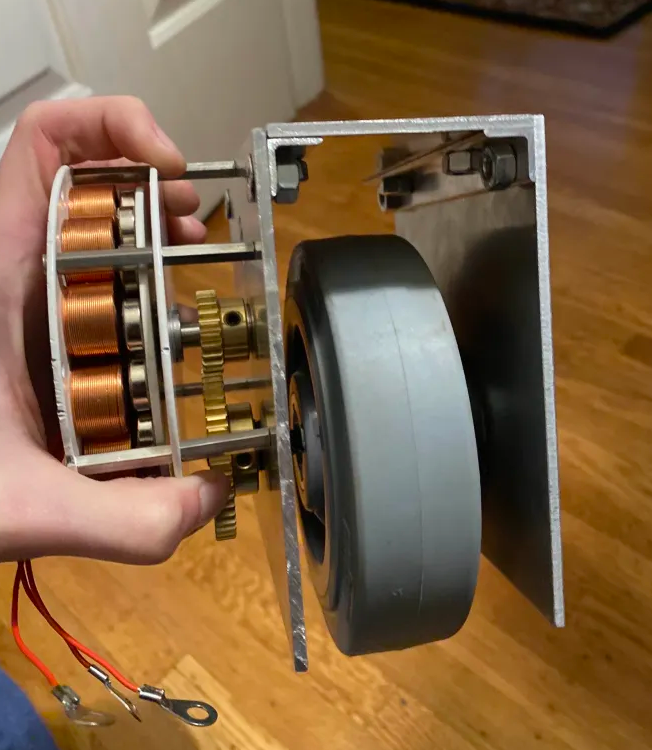

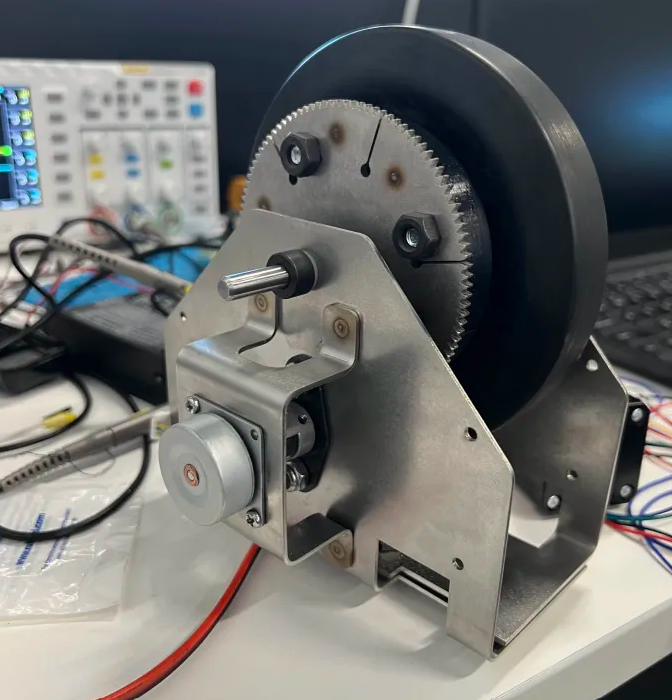

Design narrative sketch → CAD → build → pilot

The system progressed through rapid concepting and mechanical packaging, then converged through build-test-iterate cycles toward a pilot-ready configuration.

Constraints

- • High-duty cycle hardware exposed to repeated impacts, vibration, and environmental variability

- • Tight packaging constraints on carts (mounting, clearance, safety)

- • Must be maintainable by store operations (service access, replacement strategy)

- • Power generation and delivery must be reliable enough to enable real applications

- • Pilot timelines required fast iteration without sacrificing field robustness

Approach

- • Converted the “harvest energy from carts” objective into mechanical + system requirements

- • Designed packaging and mounting to support durability, safety, and serviceability

- • Built prototypes to validate energy generation, mechanical survivability, and integration assumptions

- • Iterated based on observed failure modes and deployment friction

- • Advanced toward pilot deployment with a focus on repeatability and maintainability

Key skills demonstrated

Took a core physics/system challenge and translated it into real packaging, mounting, and field-ready hardware.

Drove build-test-iterate cycles using observed failure modes and operational realities to converge on a pilot build.

Designed for high duty-cycle usage with practical service access and replacement considerations.

Ensured the physical system reliably generated and delivered usable power to enable downstream applications and impact.

I build mechanically robust hardware that solves a core systems constraint—then translate it into deployable value and impact.