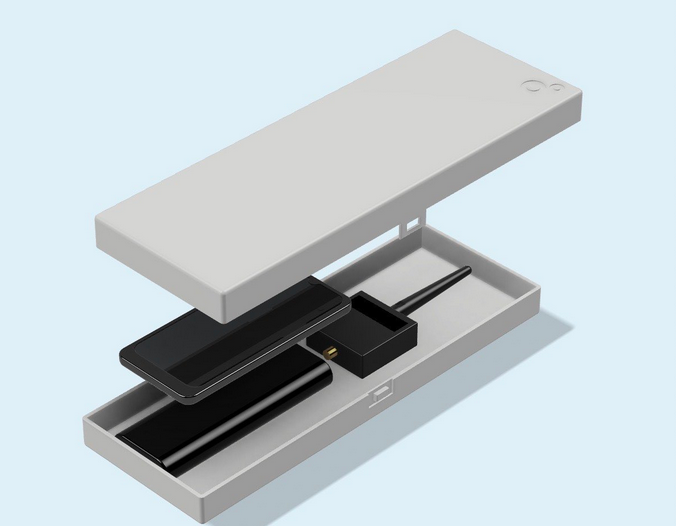

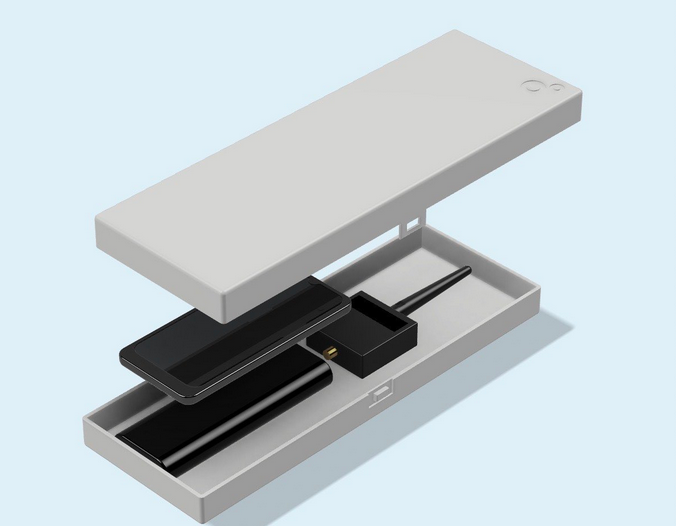

Wiliot MDK

Product design engineering of a rugged, serviceable Mobile Deployment Kit for in-store Bluetooth tag tracking.

Rugged enclosure design for real-time in-store tag tracking

The Mobile Deployment Kit (MDK) enabled real-time tracking of Bluetooth tags in stores and was designed to be robust enough for daily use on high-touch equipment across all three shifts.

Product Design Engineer (Mechanical) — designed a store-ready enclosure with a manufacturable architecture, easy cart mounting, and fast daily service access for internal components (phone, batteries, Bluetooth node).

Outcomes

Success criteria were operational: the fleet had to survive daily store use, enable consistent tag reads across all shifts, and be fast to service each morning.

Objective

Design a rugged, store-usable Mobile Deployment Kit enclosure that could be mounted to an associate topstock cart, protect sensitive components, and support daily swap/servicing—while still allowing reliable Bluetooth signal ingress/egress for tag detection.

System overview what the kit enabled

The MDK combined sensing, monitoring, and power into a field-deployable package so store operations could collect tag-read data during normal daily workflows.

- • Bluetooth node to sense tags throughout store operations

- • Phone + app for monitoring and session management

- • Batteries to power the node and phone for full-shift runtime

- • Fleet of complete units ready for small-scale deployment

- • Reliable tag reads throughout all three shifts

- • End-of-day reporting with successful read data captured

Constraints

- • High-touch environment (topstock cart shared across three shifts)

- • Robust enclosure needed, but materials/geometry had to preserve Bluetooth performance

- • Designed with DFM intent for scale (injection-mold-ready), while pilot builds were 3D printed

- • Mounting constrained to the cart, yet required quick replacement and minimal tools

- • Daily service access needed for component swaps (phone, batteries, Bluetooth node)

Mechanical design focus

Designed to withstand impacts, frequent handling, and shift-to-shift usage on high-traffic equipment without becoming a maintenance burden.

The enclosure prioritized “swap in the morning” usability—internal components could be replaced quickly to keep operations moving.

Balanced mechanical protection with Bluetooth constraints, ensuring the enclosure did not inadvertently block or degrade reads.

Pilot units were 3D printed, but the architecture was designed with injection molding and larger-scale manufacturability in mind.

Artifacts CAD → pilot hardware

With only two primary artifacts, this project is best represented as a tight end-to-end story: a DFM-minded enclosure design translated into a pilot-ready, store-mounted unit that supported daily operations.

One-line takeaway

I design field-ready enclosures that balance durability, serviceability, and RF constraints—so sensing systems can actually operate reliably in the real world.